Project Spotlight – Lead Paint Removal Services

It’s widely acknowledged that dealing with lead presents significant challenges, especially when coating surfaces containing this hazardous material. The risks and regulations surrounding lead management can create a maze of constraints, making it difficult for industries to proceed with necessary maintenance and updates without compromising safety and compliance. This is where we come in: Recoveron Industrial is a leader who navigates these intricate scenarios. With our expertise in lead abatement and surface preparation, we offer tailored solutions that comply with stringent environmental and health standards and ensure the durability and integrity of your coatings—Trust Recoveron Industrial to transform these constraints into opportunities for improvement and protection for your facilities and workforce.

Comprehensive Lead Paint Removal by Recoveron

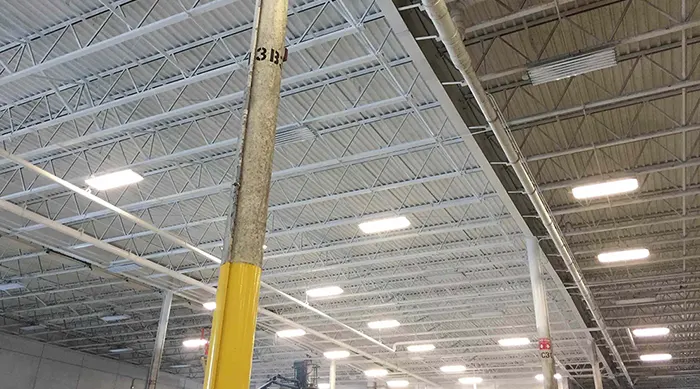

At Recoveron, we recently embarked on an ambitious industrial project that underscored our commitment to environmental safety, regulatory compliance, and meticulous operational planning. Our latest endeavor, removing hazardous lead paint from an industrial site, not only set new benchmarks in safety and efficiency but also highlighted the critical importance of comprehensive safety planning in our operations.

Advanced Air Monitoring for Uncompromised Safety

A cornerstone of our safety plan was deploying state-of-the-art air monitoring technology. Utilizing low-volume pumps, also known as air sampling pumps, provided by the State Lab of Hygiene, we established a robust system for real-time capturing and analyzing air quality. These devices, equipped with cassettes capable of recording air samples for up to eight hours, were strategically placed: two attached to technicians actively involved in the paint removal process and two positioned near the work area to ensure a comprehensive monitoring setup.

Our on-site supervisors monitored these pumps daily, ensuring precision in data collection, which is crucial for the safety of the technicians and the overall project integrity. With samples sent in daily and results anticipated within 48 hours, Recoveron maintained a proactive stance on air quality, adjusting safety protocols based on real-time data.

Rigorous Personal Protective Equipment (PPE) and Containment Measures

At the project’s onset, our technicians donned Tyvek suits, gloves, and full-face respirators, a testament to our company’s no-compromise policy on safety. This initial layer of protection remained in place until air quality tests returned negative results, reaffirming the environment’s safety. Further, our strategic deployment of containment measures showcased a preemptive approach to environmental control, with containment barriers erected and maintained until negative results were achieved for at least two consecutive days, signifying a secure and lead-free area.

Tailored Solutions and Flexible Options

Recognizing our clients’ diverse needs and timelines, we provided two distinct project options. The first option promised completion within eight to nine weeks during regular working hours, while the second option leveraged regular and overtime hours to expedite the process, aiming for a six to seven-week completion time. This flexibility allowed our clients to choose a solution best suited to their urgency and budgetary considerations.

Methodical Approach and Environmental Stewardship

Our systematic approach to project execution matched the precision of needle scalers for targeted lead paint removal. We divided the project into eight distinct sections, constructing scaffolding and containment meticulously in each area. This segmentation ensured that each area was thoroughly cleaned and cleared of lead paint before moving to the next, minimizing the risk of cross-contamination and ensuring focused attention to detail.

Waste management was handled with equal care, with Recoveron providing specialized, dedicated 55-gallon drums attached to industrial-strength vacuums. The drums were covered and sealed to safely dispose of lead paint and debris. Moreover, we used specialized wipes to clean each section, underscoring our commitment to leaving no trace behind and prioritizing environmental health and workplace safety.

Lead Abatement Conclusion

Our lead paint removal project is a testament to Recoveron’s leadership in industrial cleaning and environmental stewardship. Through our commitment to meticulous planning, advanced monitoring technology, and adaptive safety measures, we met our project goals and advanced the industry standards for safety and efficiency. This project exemplifies how cutting-edge technology, strategic preparedness, and a deep-seated commitment to safety can come together to address and overcome the challenges posed by industrial hazards.