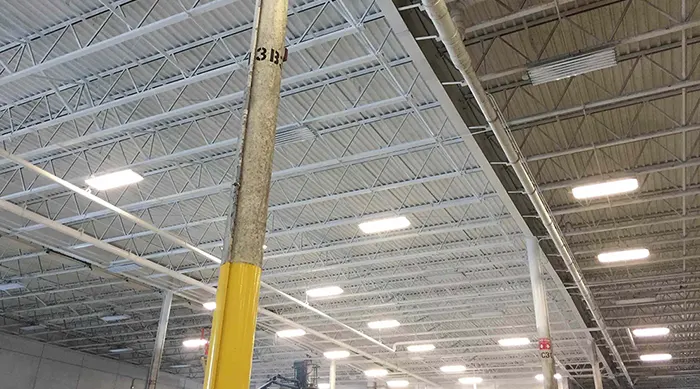

Watch for Dust

Dust can accumulate in many areas of your facility. All facilities should conduct an audit periodically to evaluate the potential for combustible dust build-up. It is very important to deep clean your workplace for dust more than once a year. Encourage employees to keep a watchful eye on dust buildup and to report it immediately.

Control Flammable Elements

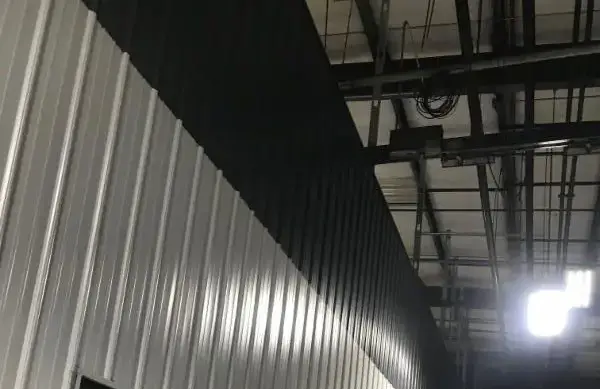

The three necessary elements needed to make fire are heat, oxygen, and fuel (dust). Volatile dust can develop from many sources like plastics, grain, bulk food products, carbon, coal, wood, etc. Combustible dust can also be byproducts from grinding, crushing, conveying, screening, and sanding. Combustible dust can also accumulate in specific areas of your facility such as receiving areas for raw material, particular production areas, maintenance, and boxing areas. Combustible dust can be managed using procedural methods such as deep cleaning, vacuum recovery cleaning, and removing compressed air from the routine clean-up procedures.

Call Recoveron

We will conduct a survey and an assessment to analyze your specific needs and resolutions to all of your combustible dust needs. Our team is highly qualified and trained to clean the dust in hard-to-reach places. After hiring us for our dust management program, you will feel confident in the safety of your workplace.